How Spandrel Glass Backsplash can Save You Time, Stress, and Money.

Table of ContentsThe 9-Minute Rule for Spandrel Glass Color Chart7 Simple Techniques For Spandrel Glass ColoursGetting The Spandrel Glass Color Chart To Work

The structural structure ensures the bearing feature, whereas the infill wall surface serves to divide inner and also external room, filling up the boxes of the outer frames.

The infill wall is an external vertical opaque sort of closure. With regard to various other classifications of wall surface, the infill wall varies from the dividers that serves to separate 2 indoor spaces, yet likewise non-load bearing, as well as from the load bearing wall. The last does the same features of the infill wall surface, hygro-thermically as well as acoustically, however does static functions too.

Some of the non-structural requirements are: fire safety, thermal comfort, acoustic convenience, resilience as well as water leakage. Fire safety and security [modify] The safety and security versus fire is just one of the requirements that is usually needed to rooms wall surfaces. As normally the more typically utilized products (blocks, bricks as well as mortar) are not fuel products, it is fairly very easy to accomplish the demands relating to the constraint of spread of fire, thermal insulation and also structural stamina, which in severe situations, need to be assured for 180 mins.

Spandrel Panels Cladding for Beginners

This demand has a straight impact on the construction of the wall surfaces. The thermal policies are demanding progressively higher values of thermal resistance to the walls. To meet these demands new items as well as building systems, which ensure that the thermal resistances asked for by the guidelines will certainly be supplied, are established.

Local habits [edit] The primary problems in the regional interaction between frame as well as infill are the formation of short beam, brief column result in the architectural aspects. The zones in which supplemental shear pressures can occur, acting locally on the extremities of the light beams as well as columns, need to be dimensioned and transversally enhanced in order to overtake securely these forces.

Rumored Buzz on Spandrel Panels Cladding

These are generally big precast concrete panels that are the height of one storey and of a size determined by the spacing of the frame. They can be either top-hung or bottom-supported. It has diamond-shaped openings over its surface, providing it an unique look. Because the material in this process can be broadened as much as 10 times the dimension it began at, the final product considers concerning a 5th what it did yet still keeps its essential integrity and also strength. These panels offer exceptional strength for a building exterior or other application. For architectural security and an enhancement to the style of your building, stairs, walkway or various other area, select these infills.

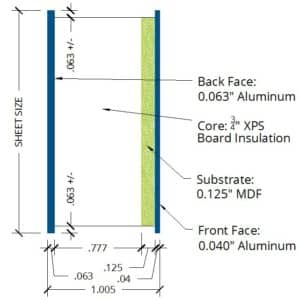

Openings in the shape you require are punched right into metal sheets to offer a strong product that stays resilient. You can obtain rounded, square, slotted and various other holes in several different patterns that benefit the design you have in mind. Infill panels are made use of in between articles of guard railing to create the barrier for fall protection on staircases, porches, and sidewalks. Perforated infill panels, woven cable panels, or laser cut panels offer intriguing ways to load the room between posts. Infill panels are typically set up on structure outsides as a drape wall surface, a rainscreen, or assistance for other cladding material. Steel infill panels provide an excellent way to add safety and security to areas that need that. They are relatively light weight and can be included or eliminated as wanted. They allow light and air with and can be developed with imagination to enhance the room and the appearance of the building. They permit for airflow and also supplies continue reading this safety and security from within, all while evaluating the view from the exterior and offering an unique and interesting style for the structure. There are many methods to cover a ceiling to conceal the joists or trusses as well as energies that run in ceilings. One means is with making use of steel infill panels, particularly when an extra commercial appearance is desired. Infill panels are a terrific method to fill out the areas of the assistance framework for canopies and also sunshades. They provide shade, layout, as well as permanency. Bus shelters, Park as well as Ride waiting locations, Band coverings, Parks, Zoos, Playgrounds, Residential housing are all areas where infill panels are utilized. Aluminium shielded infill panels are constructed with a shielding core sandwiched between 2 slim aluminium sheets. Infill panels typically utilized for windows, doors as well as drape wall surface applications, offer high performance insulation for the structure as well as offer an appealing contemporary appearance. Taking part infills create a composite architectural system with the bounding structure, enhancing the strength and tightness of the wall system as well as its resistance to earthquake as well as wind tons. Non-participating infills are outlined with architectural gaps between the infill and the boundingframework to avoid the unintentional transfer of in-plane lots from the frame into the infill. Construction of concrete masonry infilled frameworks is fairly basic. Initially, the bounding structure is built of either strengthened concrete or structural steel, after that the masonry infill is constructed in the portal space. This building and construction sequence permits the roof covering or flooring to be created before the masonry being laid, allowing for quick construction of succeeding tales or application of roof product. The system acts as a monolithic cantilever wall surface whereby small stress concentrations take place at the 4 edges, while the middle of the panel creates a roughly pure shear anxiety state. As filling continues, splitting up occurs at the user interface of the masonry and also the framework members at the off-diagonal corners. Taking part masonry infills stand up to out-of-plane loads by an arching mechanism. As out-of-plane lots raise past the elastic restriction, flexural cracking takes place in the stonework panel. This breaking(similar to that which takes place in enhanced masonry )permits for curving action to resist the applied tons, supplied the infill is created tight to the bounding structure and the infill is not also slim. If a space exists in between these details the infill as well as the frame, the infill is taken into consideration participating if the void is less than in.(9. 5 mm) as well as the determined variations, according to MSJC Code Section B3. 1.2. 1. Nonetheless, the infill can still be developed as a participating infill, offered the calculated stamina as well as tightness are reduced by half

. The optimum thickness allowed is one-eighth of the infill elevation. The MSJC Code calls for taking part infills to totally infill the bounding frame as well as have no openingspartial infills or infills with openings might not be taken into consideration as part of the side pressure standing up to system because structures with partial infills have typically not done well throughout seismic events. The in-plane style is based on a supported frame design, with the masonry infill acting as a comparable strut. The size of the strut is figured out from Formula 1(see Number 1). The term strut, developed by Stafford Smith and also Carter(ref. 2 )in the late 60s, is the characteristic stiffness specification for the infill and also gives a procedure of the loved one rigidity of the frame as well as the

infill. The diagonal strut is established within the panel as an outcome of angled tensile breaking. Flexural breaking failing is rare because separation at the masonry-frame user interface normally happens first; after that, the side pressure is resisted by the angled strut. As gone over above, the nominal shear ability is identified as the least of: the ability infill edge crushing; the horizontal element of the this content pressure in the comparable strut at a racking variation of 1 in. 2.4, determined along a bed joint. The displacement limit was discovered to be a far better forecaster of infill efficiency than a drift limit. Typically, the infill toughness is gotten to at reduced displacements for tight bounding columns, while much more versatile columns result in the toughness being managed at the 1-in.(25-mm)variation restriction. 2 is for unreinforced stonework, usage of formulas from that section does not necessarily suggest that the infill product must be unreinforced. The equations utilized in MSJC Code Section 3. 2 are extra clearly pertaining to failure along a bed joint and also are consequently better than equations from MSJC Code Area 3. The equations utilized in the code are the outcome of comparing numerous logical approaches to speculativeresults. They are toughness based. The speculative outcomes made use of for comparison were a blend of steel as well as enhanced concrete bounding frames with clay as well as concrete masonry. While some approaches presented by various scientists are fairly complex, the code equations are relatively straightforward. As out-of-plane pressures are put on the surface of the

infill, a two-way arch develops, gave that the infill is built tight to the bounding framework. The code equation versions this two-way arching action. As formerly stated, the optimum density permitted calculation for the out-of-plane ability is one-eighth of the infill height. Bounding framework participants that have various cross sectional properties are represented by balancing their residential or commercial properties for use in

the code equations. NON-PARTICIPATING INFILLS Due to the fact that non-participating infills sustain only out-of-plane tons, they must be described to avoid in-plane lots transfer into the infill. Because of this, MSJC Code Area B. 2. Connectors are not enabled to send in-plane tons. The stonework infill might be developed to cover up and down, flat, or both.